Testing a lithium cell battery requires precision and the right tools. I focus on methods that ensure accurate results while prioritizing safety. Handling these batteries with care is crucial, as improper testing can lead to hazards. In 2021, China reported over 3,000 electric vehicle fire accidents, highlighting the importance of safe battery testing. By using tools like multimeters and battery analyzers, I can assess battery health effectively. Understanding these results helps in maintaining battery performance and preventing potential risks.

Key Takeaways

- Prioritize safety by using essential gear like goggles and gloves, and set up a well-ventilated testing area free from flammable materials.

- Regularly test your lithium cell battery every few months to monitor its health and performance, helping to identify potential issues early.

- Utilize a multimeter for basic voltage testing to assess the battery’s state of charge and identify any potential faults.

- Perform visual inspections to check for physical damage or signs of wear, which can indicate the battery’s overall condition.

- Consider using advanced tools like a battery analyzer and thermal camera for comprehensive assessments of battery capacity and thermal performance.

- Understand the significance of internal resistance measurements; a high resistance can indicate aging or damage, affecting the battery’s efficiency.

- Make informed decisions about battery maintenance or replacement based on test results, ensuring optimal performance and safety.

Preparation and Safety Precautions

When I prepare to test a lithium cell battery, I prioritize safety. Understanding the potential hazards and taking necessary precautions ensures a safe testing environment.

Understanding Battery Safety

Importance of Handling with Care

Handling lithium cell batteries requires careful attention. These batteries store significant energy, which can release suddenly if mishandled. I always ensure that I handle them gently to prevent any damage. Mishandling can lead to short circuits or even fires. According to a study in the Batteries journal, understanding battery safety is crucial due to the high energy density of lithium-ion batteries.

Identifying Potential Hazards

Identifying potential hazards is a key step in battery testing. I look for signs of swelling, leakage, or unusual odors. These indicators suggest internal damage or chemical reactions. Recognizing these hazards early prevents accidents. The J. Energy Chem. journal highlights the importance of identifying these risks to ensure safe battery usage.

Safety Gear and Environment

Recommended Safety Equipment

I equip myself with essential safety gear before testing. This includes safety goggles, gloves, and a fire extinguisher. These items protect me from accidental spills or sparks. Wearing appropriate gear minimizes the risk of injury during testing.

Setting Up a Safe Testing Area

Setting up a safe testing area is vital. I choose a well-ventilated space, free from flammable materials. A clean, organized workspace reduces the chance of accidents. I ensure that all testing equipment is in good condition and properly calibrated. This setup creates a controlled environment for accurate and safe testing.

Tools Required for Testing

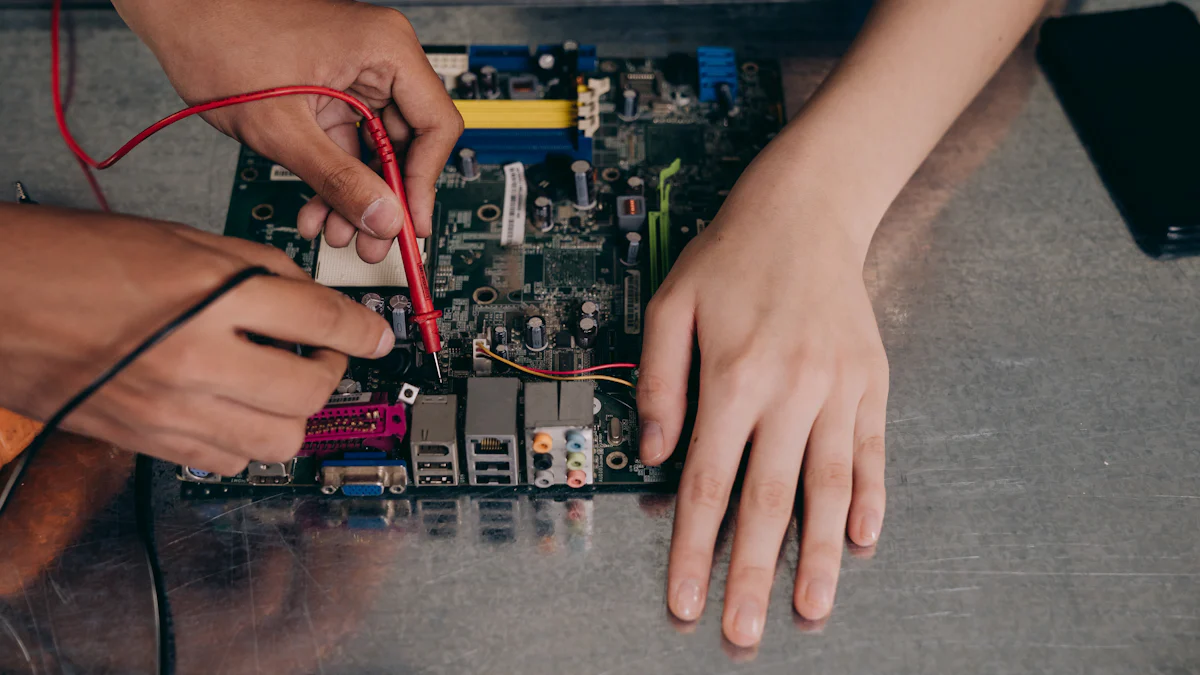

Testing a lithium cell battery effectively requires the right tools. I rely on both essential and advanced equipment to ensure accurate results and maintain battery health.

Essential Testing Tools

Multimeter

A multimeter serves as a fundamental tool in battery testing. I use it to measure the voltage of the lithium cell battery. By connecting the positive probe to the battery’s positive terminal and the negative probe to the negative terminal, I can obtain precise voltage readings. This step helps me determine the state of charge (SOC) and identify any potential issues with the battery. Regular use of a multimeter ensures that I keep track of the battery’s performance over time.

Battery Analyzer

A battery analyzer provides a more comprehensive assessment of the battery’s condition. I use it to conduct load tests, which involve applying a load to the battery while measuring the voltage drop across the terminals. This process helps me evaluate the battery’s capacity and internal resistance. By using a battery analyzer, I can detect aging and performance issues early, allowing for timely maintenance or replacement.

Optional Advanced Tools

Thermal Camera

A thermal camera offers an advanced method for testing lithium cell batteries. I use it to conduct thermal tests, which involve assessing the battery’s temperature distribution. This tool helps me identify hotspots or uneven heating, which could indicate potential problems. By monitoring the thermal performance, I can ensure the battery operates within safe temperature limits, preventing overheating and extending its lifespan.

Cycle Life Tester

A cycle life tester allows me to evaluate the battery’s longevity. I set up cycle tests to simulate the battery’s charging and discharging cycles. This tool helps me gather data on how the battery performs over time, providing insights into its durability and efficiency. By analyzing cycle life data, I can make informed decisions about battery maintenance and replacement, ensuring optimal performance for various applications.

Basic Testing Methods

Testing a lithium cell battery involves several straightforward methods that help me assess its condition and performance. These methods ensure I can identify any issues early and maintain the battery’s health.

Visual Inspection

Checking for Physical Damage

I start by visually inspecting the lithium cell battery for any physical damage. This step involves looking for cracks, dents, or any deformities on the battery’s surface. Such damage can compromise the battery’s integrity and lead to safety hazards. By identifying these issues early, I can prevent potential failures or accidents.

Identifying Signs of Wear

Next, I check for signs of wear. This includes looking for corrosion on the terminals or any discoloration on the battery casing. These signs often indicate aging or exposure to harsh conditions. Recognizing wear helps me decide if the battery needs maintenance or replacement.

Voltage Testing

Using a Multimeter

Voltage testing is a crucial step in assessing a lithium cell battery’s state of charge. I use a multimeter to measure the voltage. By connecting the positive probe to the battery’s positive terminal and the negative probe to the negative terminal, I obtain an accurate voltage reading. This measurement helps me understand the battery’s current charge level.

Understanding Voltage Readings

Interpreting the voltage readings is essential. A fully charged lithium cell battery typically shows a voltage close to its nominal value. If the reading is significantly lower, it may indicate a discharged or faulty battery. Regular voltage checks help me monitor the battery’s performance over time.

Capacity Testing

Performing a Discharge Test

To evaluate the battery’s capacity, I perform a discharge test. This involves discharging the battery under controlled conditions and measuring the time it takes to reach a specific voltage. This test provides insights into the battery’s ability to hold a charge and deliver power.

Analyzing Capacity Results

After the discharge test, I analyze the results to determine the battery’s capacity. A significant drop in capacity may suggest aging or internal issues. By understanding these results, I can make informed decisions about the battery’s future use and maintenance needs.

Internal Resistance Testing

Testing the internal resistance of a lithium cell battery provides valuable insights into its health and performance. I focus on this aspect to ensure the battery operates efficiently and safely.

Measuring Internal Resistance

To measure internal resistance, I use a battery analyzer. This tool applies a small load to the battery and measures the voltage drop. The process involves connecting the analyzer to the battery terminals and initiating the test. The analyzer calculates the resistance based on the voltage drop and the applied load. This measurement helps me understand the battery’s efficiency in delivering power. A low internal resistance indicates a healthy battery, while a high resistance suggests potential issues like aging or damage.

Scientific Research Findings:

- Ultrasonic Non-Destructive Testing methods have been developed to assess internal resistance without damaging the battery. These techniques provide accurate measurements and help in identifying aging signs early.

Interpreting Resistance Values

Interpreting the resistance values requires careful analysis. I compare the measured resistance with standard values for the specific battery type. A significant increase in resistance over time may indicate the formation of a solid electrolyte interface (SEI) or other internal changes. Understanding these values allows me to make informed decisions about battery maintenance or replacement. Regular monitoring of internal resistance helps in predicting the battery’s lifespan and ensuring optimal performance.

Scientific Research Findings:

- Studies using NMR techniques have shown that increased internal resistance often correlates with the presence of dead lithium and SEI layers. These findings emphasize the importance of regular resistance testing to maintain battery health.

Advanced Testing Techniques

Exploring advanced testing techniques allows me to gain deeper insights into the performance and longevity of a lithium cell battery. These methods help ensure that the battery operates efficiently and safely over its lifespan.

Cycle Life Testing

Setting Up a Cycle Test

To set up a cycle test, I simulate the charging and discharging cycles of the battery. This process involves using a cycle life tester, which automates the cycles and records data on the battery’s performance. I connect the battery to the tester and configure the parameters, such as charge and discharge rates. This setup helps me understand how the battery behaves under typical usage conditions. By observing the battery’s response to repeated cycles, I can assess its durability and efficiency.

Scientific Research Findings:

- Key Characteristics of Lithium Ion Cell Internal Resistance highlight that internal resistance plays a crucial role in defining battery performance. Monitoring this characteristic during cycle tests provides valuable insights into the battery’s health.

Evaluating Cycle Life Data

After completing the cycle test, I evaluate the collected data to determine the battery’s cycle life. This analysis involves examining the capacity retention and any changes in internal resistance over time. A gradual decline in capacity or an increase in resistance may indicate aging or potential issues. By understanding these trends, I can make informed decisions about battery maintenance or replacement. Regular cycle life testing ensures that I maintain optimal battery performance for various applications.

Thermal Testing

Conducting a Thermal Test

Conducting a thermal test involves assessing the battery’s temperature distribution during operation. I use a thermal camera to capture images of the battery while it charges and discharges. This tool helps me identify hotspots or uneven heating, which could signal potential problems. By monitoring the thermal performance, I ensure that the battery operates within safe temperature limits, preventing overheating and extending its lifespan.

Scientific Research Findings:

- Studies on Internal Resistance Measurement in Lithium Ion Batteries reveal that internal resistance can vary with factors like temperature. Understanding these variations during thermal tests helps in maintaining battery safety and efficiency.

Assessing Thermal Performance

Assessing thermal performance requires analyzing the thermal images and data collected during the test. I look for any abnormal temperature patterns that might indicate issues such as poor heat dissipation or internal faults. By addressing these concerns early, I can prevent potential failures and ensure the battery’s reliability. Regular thermal testing helps me maintain a safe operating environment for the battery, enhancing its overall performance and longevity.

Interpreting Test Results

Interpreting the results from testing a lithium cell battery involves careful analysis. I focus on understanding the data to make informed decisions about the battery’s health and future use.

Analyzing Data

Understanding Test Outcomes

I begin by examining the test outcomes. Each test provides specific insights into the battery’s condition. For instance, voltage readings reveal the state of charge, while internal resistance measurements indicate efficiency. By comparing these results with standard values, I can assess the battery’s performance. Non-destructive testing methods, such as ultrasonic testing and nuclear magnetic resonance, offer additional insights without damaging the battery. These advanced techniques help me identify subtle changes that might not be visible through basic tests.

Making Informed Decisions

With a clear understanding of the test outcomes, I make informed decisions regarding the battery’s future. If the data suggests a healthy battery, I continue regular monitoring to ensure ongoing performance. However, if signs of degradation appear, I consider maintenance or replacement options. This proactive approach helps me maintain optimal battery performance and safety.

Assessing Battery Health

Identifying Healthy vs. Degraded Batteries

Identifying the difference between healthy and degraded batteries is crucial. A healthy battery shows stable voltage, low internal resistance, and consistent capacity. In contrast, a degraded battery may exhibit increased resistance, reduced capacity, or irregular voltage readings. By recognizing these signs early, I can prevent potential failures and ensure the battery’s reliability.

Planning for Battery Maintenance or Replacement

Once I identify a battery’s condition, I plan for maintenance or replacement. For healthy batteries, I schedule regular checks to monitor their performance. For degraded batteries, I evaluate the extent of wear and decide whether maintenance can restore functionality or if replacement is necessary. This planning ensures that I maintain a reliable power source for my applications.

Testing a lithium cell battery involves several key steps. I start with a visual inspection, followed by voltage and capacity testing. These methods help me assess the battery’s health and efficiency. To maintain battery health, I recommend regular testing and monitoring of internal resistance. A higher resistance often indicates degradation. Keeping the battery in a cool, dry place prolongs its life. Regular testing ensures optimal performance and safety. By understanding the test results and comparing them to the battery’s specifications, I can make informed decisions about maintenance or replacement.

FAQ

What is the importance of testing lithium cell batteries?

Testing lithium cell batteries is crucial for determining their capacity, lifespan, safety, and efficiency. Regular testing helps identify potential issues before they become serious, ensuring the reliability and safety of batteries used in consumer electronics, electric vehicles, and other applications.

How often should I test my lithium cell battery?

I recommend testing your lithium cell battery every few months. Regular testing helps monitor the battery’s health and performance. This practice ensures that you can address any issues early and maintain optimal battery function.

What tools do I need to test a lithium cell battery?

To test a lithium cell battery, I use essential tools like a multimeter and a battery analyzer. These tools help measure voltage, capacity, and internal resistance. For more advanced testing, I might use a thermal camera or a cycle life tester.

How do I ensure safety while testing lithium cell batteries?

Safety is my top priority when testing lithium cell batteries. I wear safety gear like goggles and gloves. I also set up a well-ventilated testing area free from flammable materials. Handling batteries with care prevents accidents and ensures a safe testing environment.

Can I test a lithium cell battery without professional equipment?

Yes, you can perform basic tests like visual inspection and voltage testing with a multimeter. These tests provide valuable insights into the battery’s condition. However, for comprehensive assessments, I recommend using professional equipment like a battery analyzer.

What does a high internal resistance indicate?

A high internal resistance often indicates aging or damage within the battery. It suggests that the battery may not deliver power efficiently. Regular monitoring of internal resistance helps predict the battery’s lifespan and ensures optimal performance.

How can I interpret voltage readings from a multimeter?

Interpreting voltage readings involves comparing them to the battery’s nominal voltage. A fully charged lithium cell battery typically shows a voltage close to its nominal value. A significantly lower reading may indicate a discharged or faulty battery.

What are the signs of a degraded battery?

Signs of a degraded battery include increased internal resistance, reduced capacity, and irregular voltage readings. Recognizing these signs early helps prevent potential failures and ensures the battery’s reliability.

How do I decide between maintaining or replacing a battery?

I decide based on the battery’s condition. If the battery shows stable voltage, low internal resistance, and consistent capacity, I continue regular monitoring. If signs of degradation appear, I consider maintenance or replacement options to maintain a reliable power source.

Why is thermal testing important for lithium cell batteries?

Thermal testing helps assess the battery’s temperature distribution during operation. It identifies hotspots or uneven heating, which could signal potential problems. Monitoring thermal performance ensures the battery operates within safe temperature limits, preventing overheating and extending its lifespan.

Post time: Dec-12-2024